The problem with conventional welding is with controlling the tools. When you can control all the machining variables you can get the best results. This includes control over machine tools, tool grip, weld environment, and cutting tools.

These days we like lighter devices and all the appliances at home have changed to intelligent design. Making these products requires different types of machining and welding as they have sensitive components. A lot of precision is required when you work on smaller products as compared to parts and components for larger products. Most small or smart devices that have microcircuits use some sort of chips.

The devices, tools, and appliances that we use today are made using precision machining. Due to advancements in technology most of the equipment used for welding and machining is now computerized. Operators can set their work settings and these can be used time over again to get the same precise results. With CNC machining it is now easier to get precise results. You can use the CAD/CAM drawings from your computer to create various products including parts for machines, automobiles, and items for the construction industry.

Many people are making a lot of money making chips using these machines. Where machining details are small CNC machines work out well. Miniature cutting tools are used for making slots in chips. You can use a 1” diameter rougher to a .032” precision end mill to make slots. While making slots, pressure and force is placed on the cutting edge of the tool. The tools slow down with pressure and there is also wear and tear. For cutting small slots it is important to choose the right miniature tool so you can create miniature slots successfully. For best chip evacuation use the right amount of flutes on the tool. For aluminum and nonferrous metals use 2 or 3 flutes while for steel you will need 4 flutes. This is so because steel is a lot harder than aluminum or nonferrous metals. With a lower flute count, there is no clogging, and chips can evacuate easily.

If you are making slots with miniature tools there may be concerns such as tool rigidity, deflection, and core strength. Working with smaller tools is very different than working with traditional slotting. When you are machining details rigidity and core strength are the key. Your tools have to last you longer and therefore need to be rigid enough. This is only possible with a larger flute count. So, try to use as many flutes you can.

With slotting, besides ensuring your tool has a hardcore you also need to have a look at the corner strength. It is good to put a corner radius on your tool, to improve the corner strength. If you need stronger tip geometry, using a ball nose end mill always helps. The ball nose end mill will give you the strongest tip of the three most common types of profiles. The geometry on the ball nose will allow for faster cutting times. The correct lead angle on the ball nose will give your instrument more life. It also decreases the cycle times. With miniature tooling, precision and accuracy are of great importance if you are slotting or roughing or making holes in parts. You also have to ensure axial passes have good depth. Take light passes with several step downs.

A large variety of tooling options are available to fulfill your slotting needs. You can find both small and miniature tools online for CNC machining. If you are not familiar with CNC machining it is a good idea to call a CNC machining company and get the advice you need. They will help you select the right equipment and will help you with your machining projects. A lot of the time it is easier and more cost-efficient for companies to outsource their work to a third party. Some companies working in the market have a very good reputation and a commendable client list. They will take care of your projects within your budget.

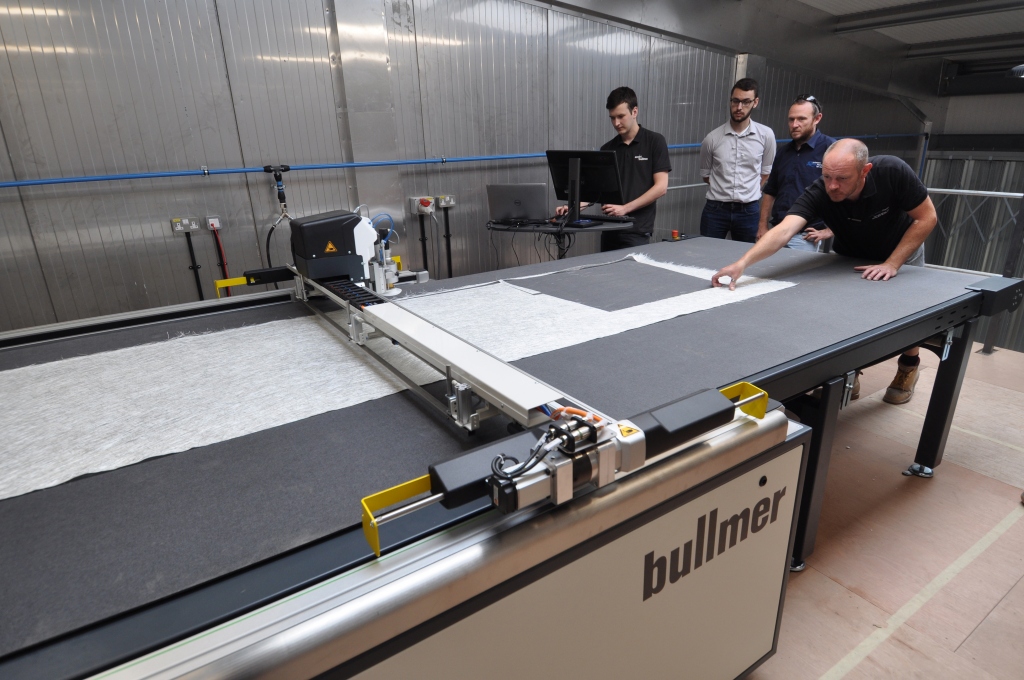

Machining requires a proper temperature-controlled environment. The changes in temperature can cause structural changes that depend on the mass of the machine. This convection can be different from one machine to another. The CNC machines work best in their own thermally controlled environment. Some machining companies use a multi-layer thermal enclosure to maintain uniform temperature distribution. The airflow and its temperature are well monitored.

If you need to get parts made you will need a proto. If you do not have a proto you will have to get one developed. All the parts or components you require can be made by the CNC machining company in a day or two. Artist can also get their artworks developed on any type of metal, wood and composite materials at a low cost